Turbochargers work by using exhaust gases to spin a turbine which compresses the incoming air. This allows engines to burn more fuel and produce more power.

This makes the engine better and more fuel efficient so turbochargers are a must in modern high performance and eco friendly vehicles. They change the engine technologya.

What is a Turbocharger?

A turbocharger or turbo or turbo is a power booster. Uses exhaust gases to spin a turbine. The turbine compresses air before it enters the combustion chamber. Compressed air means better fuel combustion.

Turbochargers help engines produce more power without increasing engine size. By forcing extra air into the engine, turbos improve efficiency. This results in better performance and fuel economy.

Many modern motor vehicle use turbochargers. They enhance the driving experience and reduce emissions. Turbos are key components in both high-performance and eco-friendly engines.

References

- Turbocharger. Wikipedia. Retrieved from https://en.wikipedia.org/wiki/Turbocharger

- What is a Turbocharger and How Does It Work?. Eagle Ridge GM. Retrieved from

How Many Types of Turbochargers?

Here are the types of Turbochargers used in Automotive engine:

- Single-Turbo: Uses one turbine and compressor. It is simple and boosts engine power efficiently.

- Twin-Turbo: Uses two turbochargers. They can be sequential or parallel, enhancing performance at various engine speeds.

- Twin-Scroll Turbo: Separates exhaust pulses for better efficiency and reduced turbo lag.

- Variable Geometry Turbo (VGT): Adjusts the turbine’s angle to optimize performance across different engine speeds.

- Variable Twin Scroll Turbo: Combines twin-scroll and variable geometry features for improved efficiency and responsiveness.

- Electric Turbo: Uses an electric motor to spin the turbine, reducing lag and improving low-speed performance.

References

- Turbocharger Efficiency. MIT DSpace. Retrieved from

- Types of Turbocharger. Melett. Retrieved from

How Does a Turbocharger Work?

- Exhaust Gases Enter: Exhaust gases from the engine flow into the turbocharger.

- Turbine Spins: These gases spin a turbine connected to a shaft.

- Compressor Spins: The spinning turbine drives a compressor on the other end of the shaft.

- Air Intake: The compressor draws in outside air and compresses it.

- Compressed Air Enters Engine: The compressed air flows into the engine’s combustion chamber.

- Improved Combustion: More air allows for better fuel combustion, which increases engine power.

- Exhaust Exits: Finally, the exhaust gases exit through the exhaust outlet, completing the cycle.

References

- How a Turbocharger Works. Cummins. Retrieved from

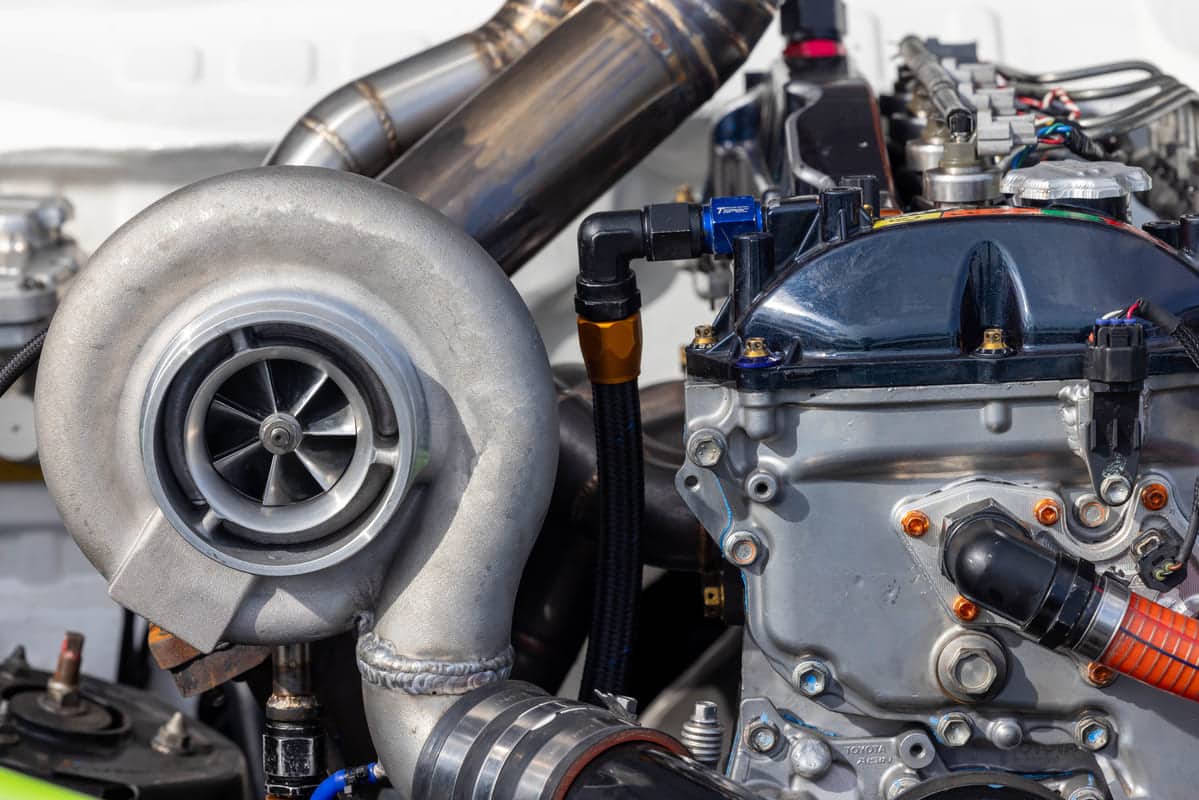

What are the Parts of a Turbocharger?

There are many different turbochargers used on diesel and petrol engines across various industries. While these turbochargers differ in size, shape, and configuration, they all work similarly and share the same basic parts.

Compressor Housing: The compressor housing gathers and compresses clean air before forcing it into the engine. It houses the compressor . Typically made from aluminum, it features a spiral-shaped design for optimal airflow and pressure.

Compressor Wheel: The compressor wheel, usually made from lightweight aluminum, sits inside the compressor housing. It spins at high speed, pulling in air, compressing it, and forcing it into the engine through the spiral housing.

Compressor Ring: This circular piston ring provides a seal between the thrust collar and the back plate of the turbocharger. It controls oil and prevents contaminants from entering the bearing system from the compressor.

Back Plate: Also known as the seal plate, the back plate connects the bearing housing to the compressor housing and retains the thrust bearing system. It acts as a sealed barrier, preventing compressed air from entering the bearing housing.

Bearing Housing: The bearing housing contains the thrust bearing and journal bearings, providing them with oil circuits for free operation. Some turbochargers also feature water-cooling systems here. Typically, it is made from heavyweight cast iron.

Thrust Bearing: Located inside the bearing housing, the thrust bearing controls axial movement (in and out) of the turbine shaft between the compressor wheel and the turbine wheel. Well-lubricated with oil, it eliminates friction and prevents wear.

Journal Bearing: Also inside the bearing housing, journal bearings control the radial load. They support the rotating parts of the turbo, ensuring they spin freely without much wobbling. Bearing clips hold journal bearings in place.

Heat Shield: Located at the back of the bearing housing, between the bearing housing and the turbine wheel’s back face, the heat shield protects turbocharger parts from exhaust gases’ heat.

References

- Turbo Technology: Turbocharger Parts and What They Do. AET Turbos. Retrieved from

How Much Horsepower Does a Turbo Add?

A turbocharger can significantly boost an engine’s horsepower. On average, a turbo can add between 30% to 40% more horsepower. The exact increase depends on the engine and the turbocharger’s size.

For instance, a 200-horsepower engine could see gains of 60 to 80 horsepower with a turbo. High-performance turbos can offer even larger increases. However, tuning and supporting modifications are often necessary for optimal gains.

Aftermarket turbos vary in efficiency and power output. Proper installation and tuning ensure maximum performance and reliability. Always consult with a professional when adding a turbo to your engine.

Why Turbocharger Used in Diesel Engines?

Below are the key advantages of a turbocharger in diesel engines:

Enhanced Efficiency: Turbochargers compress intake air, allowing more fuel to burn efficiently. This boosts engine performance without increasing displacement.

Increased Power: By forcing more air into the engine, turbochargers significantly increase horsepower and torque. This is especially beneficial for heavy-duty applications.

Reduced Emissions: Improved combustion from turbocharging results in fewer unburned fuel particles and lower emission levels, making diesel engines cleaner.

Better Fuel Economy: Turbocharged diesel engines achieve higher power with less fuel consumption, enhancing overall fuel efficiency.

Optimized for Low RPM: Diesel engines operate well at low RPMs, making them ideal for turbocharging. This maximizes power output without straining the engine.

References

- Diesel Turbocharger Assemblies. Central Diesel Inc. Retrieved from https://www.centraldieselinc.com/capabilities/diesel-turbocharger-assemblies/